NVH, Performance, and Homologation Testing

To be marketed in the main global markets—Europe, China, Japan, USA, India, Brazil, and others—braking system components such as discs, calipers, pads, and shoes must demonstrate high levels of performance, reliability, comfort, and safety. This means passing a series of specific tests required by national and international regulations and manufacturer (OEM) specifications, which verify the behavior of materials and systems under standardized and repeatable conditions.

Performance Testing

Performance tests evaluate the braking capacity, fade resistance, thermal resistance, wear, and friction stability of components. These tests are fundamental to ensuring that brakes maintain consistent and predictable behavior over time, even under extreme conditions.

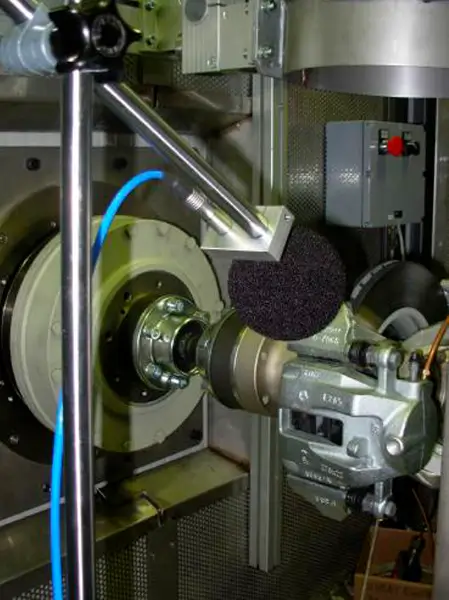

NVH Testing (Noise, Vibration, Harshness)

Acoustic and vibrational comfort is an increasingly critical requirement for both traditional and electric vehicles. NVH tests evaluate:

- Noise (squeal, groan, click, etc.)

- Vibrations transmitted to the pedal and vehicle body

- Harshness, i.e., the user’s subjective perception of discomfort

TecSA R&D is capable of reproducing, measuring, and analyzing all typical brake system NVH phenomena, both in controlled environments (anechoic chambers, dedicated NVH test benches) and on real vehicles.

Applied Regulations and Standards

A (non-exhaustive) list of the most frequently applied standards and regulations includes:

PERFORMANCE AND DURABILITY

- ISO 26865, ISO 26866, ISO 26867, ISO 22563

- SAE J2522 (AK Master), SAE J2707, SAE J2115, SAE J3080

- JASO C406, JASO C407

- ECE-R90, ECE-R13, ECE-R78

- UIC 541 (Railway)

- AMS (Aircraft Material Specifications)

- EuroSpec / GlobalSpec

NVH

- SAE J2521 (Squeal Noise Matrix Procedure)

- SAE J2598 (Disc Thickness Variation – DTV)

Homologation Services

The TecSA R&D laboratory is fully equipped with dedicated test benches, high-resolution measurement instrumentation, and highly specialized personnel.

In collaboration with Certification Bodies and in accordance with EU and international directives, we support our Clients in all phases of the homologation process:

- Planning and definition of the test plan

- Execution of tests according to the required standards

- Data collection, processing, and validation

- Preparation of technical reports for the certifying body

- Assistance up to the issuance of the homologation

Additional competencies

Beyond standard tests, TecSA R&D can:

- Develop custom procedures for Client-specific tests

- Perform vehicle-to-test-bench correlations to validate results obtained in the laboratory

- Support product engineering with root-cause analysis and improvement proposals

- Conduct testing under controlled climatic conditions (cold, heat, humidity)

TecSA R&D is the ideal partner for those who need to validate, optimize, and homologate their braking components with reduced lead times and the highest level of reliability.