OEM, Tier 1 and Tier 2 Testing

Vehicle manufacturers (OEMs) and major braking system suppliers (Tier 1) impose increasingly rigorous technical specifications to guarantee the performance, durability, comfort, and safety of components. These specifications go far beyond legislative standards and are often customized for platform, model, or target market.

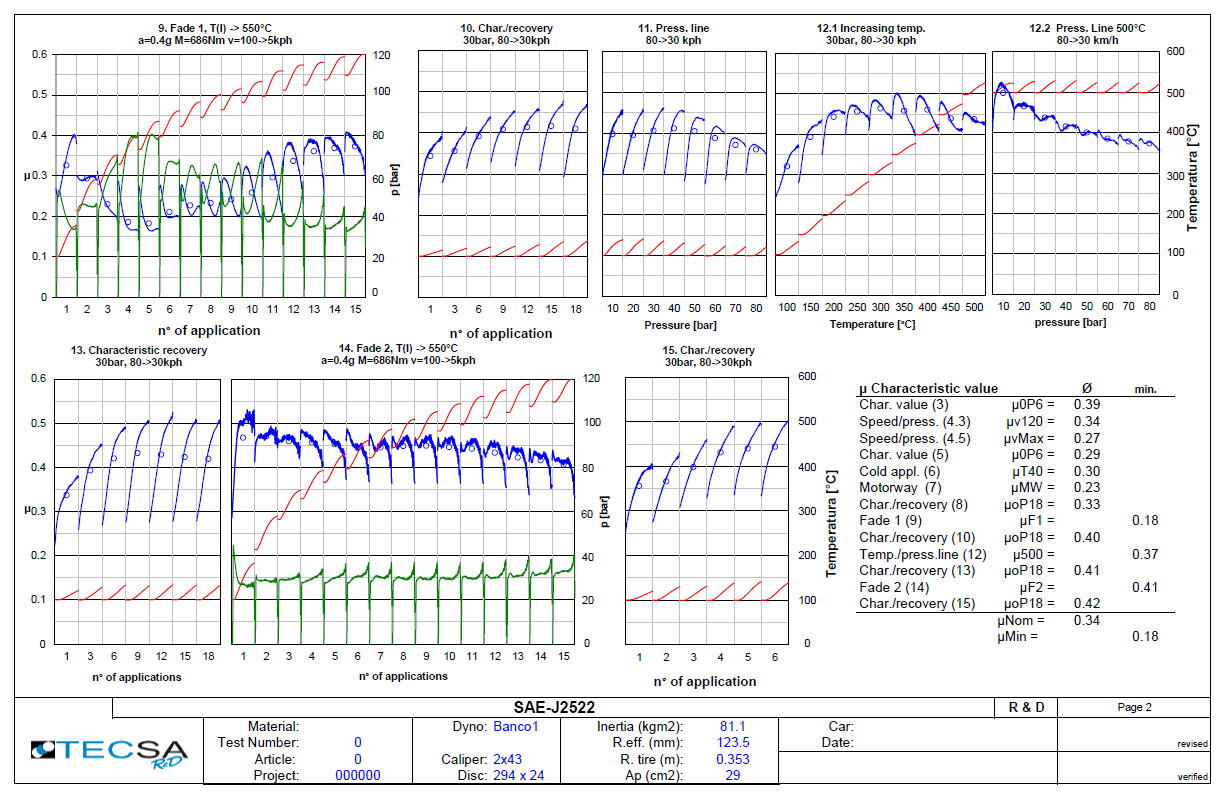

Tier 2 suppliers (providing components such as discs, pads, shoes, calipers) must demonstrate full compliance with these specifications through dedicated tests, often performed on dynamometric test benches using proprietary procedures not replicable on standard industrial equipment.

TecSA R&D: A Partner for the Entire Supply Chain

The TecSA R&D laboratory is certified and recognized by numerous OEMs and Tier 1 suppliers as a reference laboratory for performing tests according to proprietary specifications. We are capable of:

- Executing official procedures provided by OEMs/Tier 1s

- Adapting or developing new test procedures based on client specifications

- Correlating test bench data with road/vehicle data

- Supporting product engineering with root-cause analysis and comprehensive technical reports

Examples of Regularly Performed OEM/Tier 1 Procedures

Stellantis (ex-FCA)

- 90210 — Brake Disc: Wear and cracking tests

- 90244 — Brake Pad: Performance and aggressiveness tests

Fiat Legacy

- 7H2000 — Pad Durability and Wear Tests

- 7H4000 — Fading and Recovery Tests

- 7H4020 — Disc Aggressiveness Tests

- 7H4030 — Corrosion and Sticking Tests

Renault-Nissan-Mitsubishi Alliance

- Renault “Ville Taxi” — Severe urban cycle for taxis

- Renault “Cold Performance” — Low-temperature performance tests

- Nissan “Disk Thickness Variation” — DTV and Taper Tests

WLTP & NEDC Related

- Residual Torque (Drag Torque)

- Brake Dust Measurement (PM10, PM2.5)

- Regenerative Braking Blending (Hybrid/EV vehicles)

OEM-Specific NVH

- Squeal Matrix 16-24 Points (Bosch, Continental, ZF)

- Creep Groan, Judder, Wire-brush, Cold Squeal

LACT — Los Angeles City Taxi

- Real-world Los Angeles Taxi Cycle (650 stops, 180 km)

- Pad Wear, Disc Wear, Cracking

- Comparison vs. OE/Reference Part

Other Procedures Upon Request

- BMW GS 90007, GS 97002

- VW TL 110, PV 3211, PV 3213

- Mercedes MBN 31074-7

- Ford ESA-M2C 246-A

- Toyota TSK 0116G

- Hyundai/Kia MS 631-5, MS 621-05

- GMW 14922, GMW 15083

Dedicated Equipment

- Dynamometric Test Benches (Inertia & Drag)

- Original OEM Flanges or certified replicas

- Climate Chambers (-40 °C to +60 °C)

- Dust Sampling Systems (Gravimetric & Optical)

- Clean Room for analysis in a controlled atmosphere

Fast Turnaround, Reliable Results

Thanks to our mechanical and digital proximity with our clients, we can:

- Deliver preliminary reports within 24-48 hours

- Modify test bench setups within the same day

- Replicate anomalous conditions encountered on the road

TecSA R&D is the independent laboratory specialized in testing according to OEM, Tier 1, and Tier 2 specifications, enabling you to accelerate time-to-market and reduce the risk of non-compliance.

Contact us for a dedicated checklist for your specification: we will respond within 24 hours with a turnkey test plan.